3D printing technology, renowned for its rapid, versatile, and precise manufacturing capabilities, finds extensive applications across healthcare, aerospace, automotive, architecture, and consumer goods sectors. It’s a transformative force in the manufacturing landscape. Industrial-grade 3D printers, with their ability to materialize products into three-dimensional forms, transcend the limitations of traditional two-dimensional prints. This evolution significantly disrupts traditional printing paradigms, serving as a linchpin for various industry advancements and establishing an interconnected industrial ecosystem.

Diverse Applications of 3D Printing

ⅠRevolutionizing Healthcare

Precision Medical Instruments: In the healthcare domain, 3D printing revolutionizes the production of complex medical instruments such as surgical guides, artificial joints, and prosthetics. These bespoke instruments cater to individual patient needs, enhancing treatment precision and efficacy.

Customized Implants: Leveraging patient-specific CT or MRI images, 3D printing precisely crafts implants like artificial bones, cochlear implants, and dental prosthetics, ensuring superior tissue compatibility, thereby reducing surgical risks and postoperative complications.

Simulation Models: Creating precise three-dimensional models from CT or MR images aids in pre-surgical simulation and postoperative rehabilitation training, ultimately enhancing surgical precision and safety.

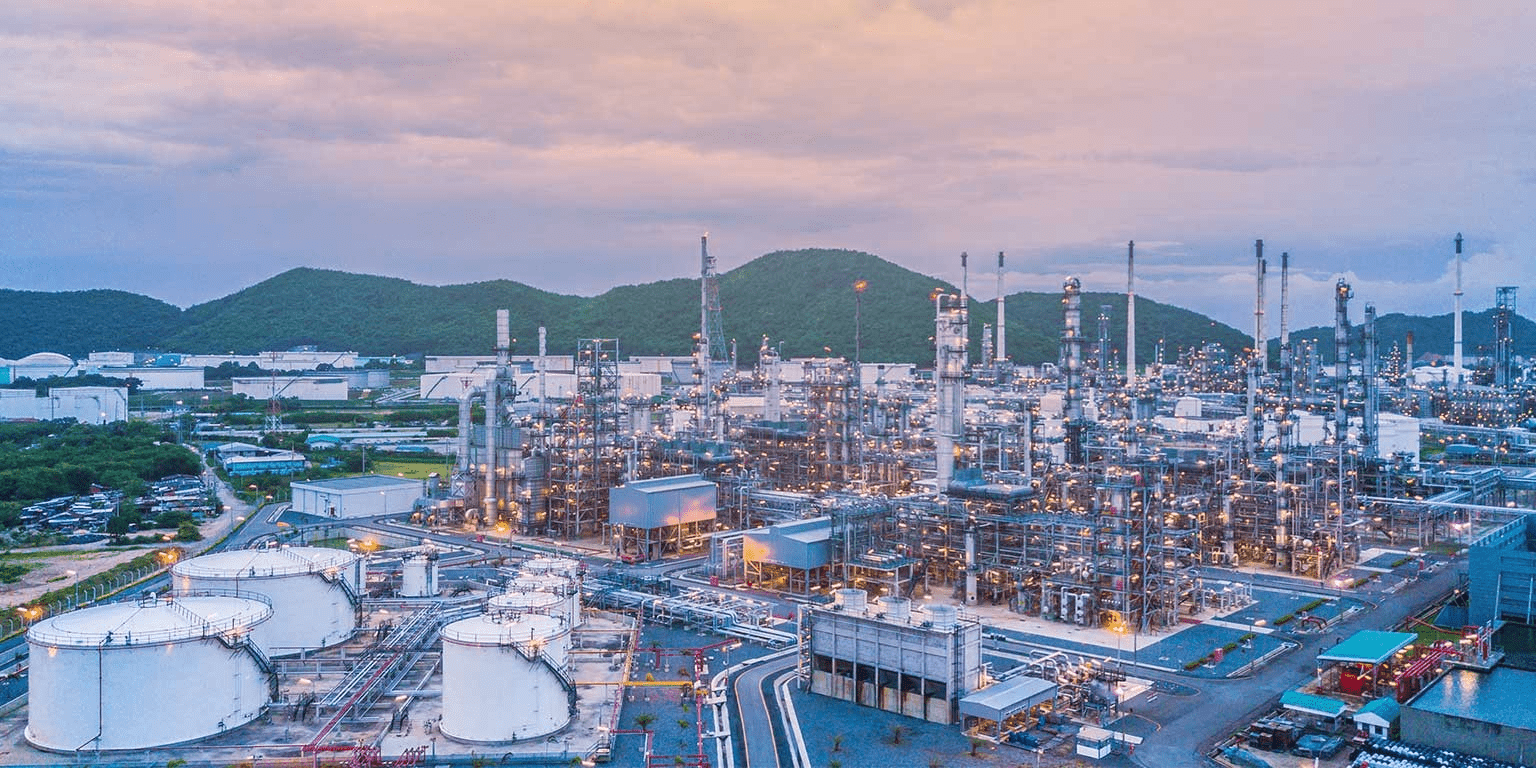

Ⅱ Aerospace Advancements

Complex Component Fabrication: Within the aerospace sector, 3D printing plays a pivotal role in producing intricate components like engine parts, fuel nozzles, and air ducts, reducing manufacturing costs and cycles while significantly reducing component weight and improving performance, thereby reducing fuel consumption and emissions.

Ⅲ Automotive Innovation

Streamlining Automotive Parts Production: In the automotive industry, 3D printing expedites research and production cycles for vehicle components, reducing costs, enabling personalized customization, and facilitating small-batch production.

Ⅳ Architectural Evolution

Efficient Construction and Design: Embracing 3D printing in architecture streamlines construction processes, permits personalized designs, minimizes waste, saves time, enables precise material control, and optimizes building safety and sustainability.

Ⅴ Consumer Goods Revolution

Tailored Product Manufacturing: 3D printing technology in the consumer goods sector focuses on crafting personalized products like shoes, jewelry, and eyewear, addressing individual consumer demands, minimizing production and inventory costs, while enhancing product quality and accuracy.

NDSpace3D Resin’s Strategic Applications

1. Model Figurines

NDSpace3D resin enables the creation of highly detailed and customizable model figurines, captivating enthusiasts and collectors with intricate designs.It is loved by our customers for its ultra-high precision, unique frosted feel, and premium luster.

2. Jewelry Casting

The resin’s capabilities revolutionize jewelry casting, crafting intricate designs that redefine elegance and precision.Reduces sanding time, improves model silky smoothness, and is more conducive to casting, while subdividing the casting, using different casting resins for large and small parts to get better results.

3. Industrial Applications

Leveraging NDSpace3D resin ensures precision in industrial manufacturing, producing durable and high-quality components.The advantages of multiple properties, high precision, high strength, high toughness, high temperature resistance, response to a variety of complex environments, etc., make it possible to find the right material for all applications of parts.

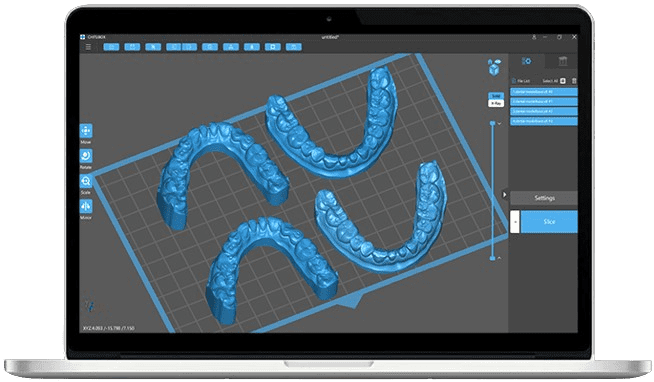

4. Dental Medical Applications

The resin’s precision is pivotal in dental healthcare, facilitating customized interventions that optimize patient care and treatment outcomes.Specialized medical resins, from dental to surgical equipment.

Multi-departmental, multi-laboratory division of labor and joint work make our applications in the corresponding fields very mature and very professional!

Shaping the Future of Industries

The amalgamation of 3D printing’s extensive applications and NDSpace3D resin’s strategic focuses underscores their combined transformative power. Together, they drive industries towards a future characterized by innovation, precision, and boundless possibilities.