Introduction

In 3D printing, UV resin plays a crucial role as a UV-curable material. Understanding its key characteristics is essential for professionals and enthusiasts in the industry. This blog will provide a comprehensive overview of the composition, characteristics, applications, and importance of prototyping with UV resin.

Definition and Composition of UV Resin

UV resin, a UV-curable material, comprises monomers, oligomers, and photoinitiators. It is closely related to 3D printing technologies such as SLA, DLP, and LCD, making it a cornerstone of modern additive manufacturing.

Key Characteristics of UV Resin for 3D Printing

Low Viscosity

UV resin’s low viscosity is vital for efficient handling and usage, significantly impacting the printing process’s overall efficiency.

Minimal Curing Shrinkage

The minimal curing shrinkage of UV resin ensures the maintenance of model accuracy and shape, greatly contributing to the stability of printed objects.

Rapid Curing Rate

Fast curing plays a pivotal role in enhancing production efficiency, setting UV resin apart from traditional curing rates in 3D printing materials.

Low Swelling

The minimal post-curing swelling of UV resin is critical for maintaining object stability and ensuring high print quality.

High Photosensitivity

With its sensitivity to specific UV wavelengths, UV resin initiates the polymerization reaction quickly, making it a reliable choice for 3D printing.

High Degree of Curing

Achieving a high curing degree with UV resin is paramount for print quality assurance, directly influencing the strength and durability of printed objects.

High Wet State Strength

Maintaining strength even in moist conditions makes UV resin versatile and reliable for printed prototypes across various industries.

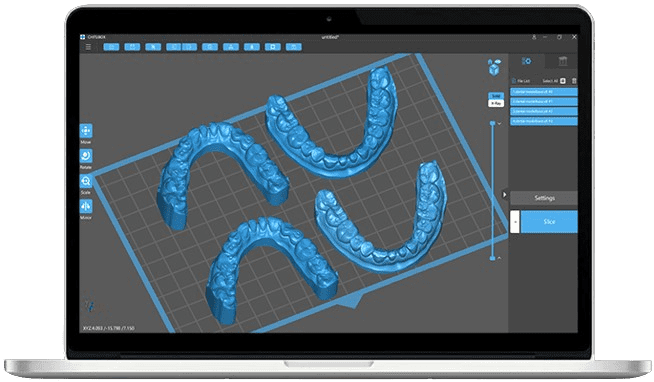

Applications of UV Resin in 3D Printing

UV resin finds diverse applications in different industries, with compelling case studies illustrating real-world usage scenarios. Its potential for customization and innovation in product development positions it as a valuable asset in modern manufacturing.

Importance of Prototyping with UV Resin

UV resin accelerates product development and iteration, contributing to cost-effective prototyping and design validation. Its impact on enhancing overall manufacturing efficiency and competitiveness cannot be overlooked.

Conclusion

Understanding the characteristics and applications of UV resin is crucial for advancing the 3D printing industry. Embracing these characteristics and utilizing UV resin can lead to innovative solutions and enhanced competitiveness. It’s time to explore and adopt UV resin in the 3D printing industry.

In conclusion, the low viscosity, minimal curing shrinkage, and rapid curing rate of 3D printing UV resin are essential for professionals and enthusiasts in the industry. Discover its applications and importance in prototyping.

.png)